Twin wall elbow

- Commodity name: Twin wall elbow

Product Description

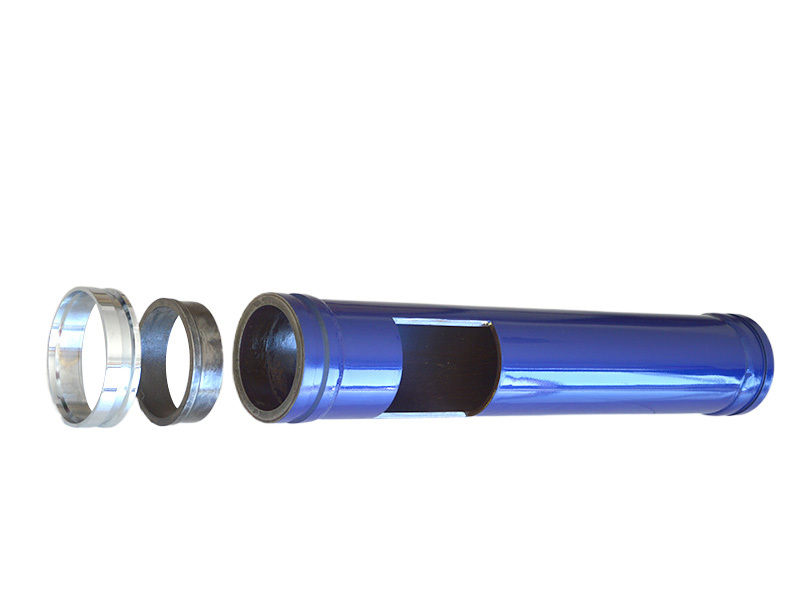

Double Layer Wear Resistant Elbow for Concrete Pump Truck

Outer protective layer

According to the wear situation at the end, both ends of the elbow are designed with a 35mm long thickened wear-resistant casing made of high chromium cast iron with a hardness of over HRC62.

Inner Wear-resistant Layer

Regarding the wear analysis of the elbow, this part of the elbow undergoes the most severe wear and the greatest impact force, which is the first area to fail. To address this, uneven thickness is used, gradually increasing from both ends towards the middle, and gradually increasing from both sides towards the middle.

According to the situation of little wear on the inner side of the elbow, a 6mm wear-resistant layer is used for the lower half of the elbow.

The wear law of elbows

The function of elbows is to change the flow direction of the concrete, so the impact and wear force on the outer arc surface of the elbow is the greatest, especially at the end of the elbow, which is subjected to the greatest impact force and fails the fastest.

Technological innovation of elbows.

Structural innovation: dual-layer,split structure, gradual thickening from both ends and sides towards the middle to address wear on the outer arc surface.

Material matching: high-carbon and high-toughness high chromium cast iron is used for the easily worn outer arc, while cost-effective bearing steel is used for the inner arc.

Process innovation: multiple processes are used, such as casting for the outer arc and die forging for the inner ball, and combination welding.

Precise reinforcement of vulnerable areas

▲Improved wear resistance of materials invulnerable areas.

▲Different thickness design of wear-resistant layer invulnerable areas.

Wear-resistant material matching

▲Developed a high-carbon, high-chromium, high-toughness cast iron through collaboration with peers and universities, with excellent wear resistance, impact resistance, high toughness, and strength.

▲Cost-effective bearing steel material is used for the wear-resistant layer of the inner arc, which is formed by die forging.

Multiple process combinations

▲Multiple process combinations achieve mass production of parts with reduced costs.

▲Casting is used for the inner liner of the outer arc , and molding is used for the outer layer; Double-layer integral die forging and integral quenching are used for the inner arc. The precision of the inner and outer arcs is guaranteed by special machine tools, and automatic welding machines are used for welding.

| Name | Specification | Material | Weight | Working press | Life time |

| Normal elbow | R275*90DE | Cast steel | 16kg | 160bar | 25.000CBM |

| R275*45DE | Cast steel | 9kg | 160bar | 25.000CBM | |

| R275*30DE | Cast steel | 8kg | 160bar | 25.000CBM | |

| Heavy elbow | R275*90DE | Cast steel | 18kg | 180bar | 35.000CBM |

| Twin wall elbow | R275*90DE | Wear material | 17kg | 180bar | 60.000CBM |

| R275*45DE | Wear material | 9.5kg | 180bar | 60.000CBM | |

| R275*30DE | Wear material | 8.5kg | 180bar | 60.000CBM | |

| Big diameter elbow | R1000*90DE | ST52 | 23kg | 150bar | 20.000CBM |

| R750*90DE | ST52 | 17kg | 150bar | 20.000CBM | |

| R500*90DE | ST52 | 12kg | 150bar | 20.000CBM |

Production strength

Customized Process

Consult customer service

Communication details

Determine the plan

Product quotation

Product sampling

Determine the sample

Order payment

Determine delivery date

Volume production

Timely delivery

After-sale service

After-sales evaluation

Customer feedback

FAQ

Are you a manufacturer or trading company?

We are manufacturer.

What are your strengths?

First of all, we are manufacturer, so the prices are more competitive than trading companies.

Second, communicating with the factory is very effective, which will save you more time.

Third, we also have several partners who provide related products to meet your needs.

Where is your factory located?

Our factory is in Cangzhou City, Hebei Province, China. It is near to Tianjin Port, so the transportation is very convenient.

I want to make our logo on the product, is it okay?

Yes, it's totally okay. We can provide OEM. What you should do is sending us your logo, brand name or picture. Leave other things to us.

Delivery

Key words:

prev

next

What Else Might You Need?