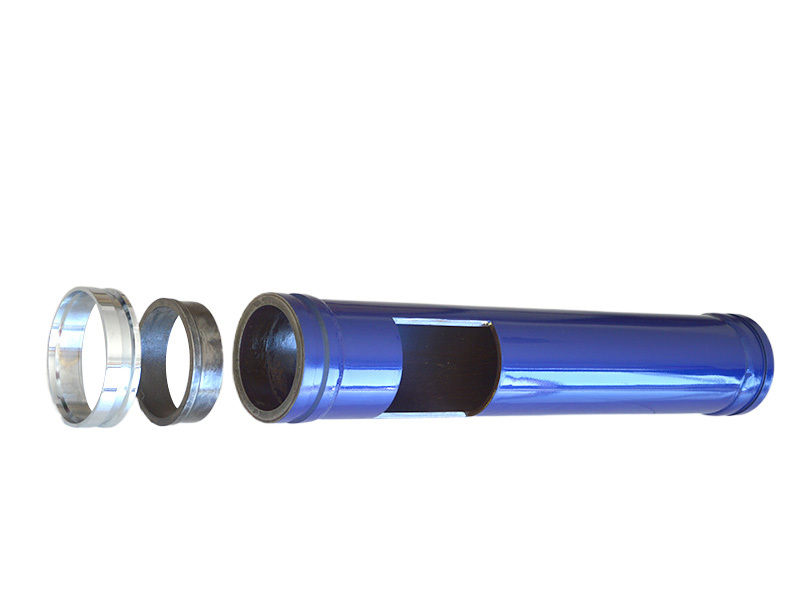

Seamless Steel Pipe

- Commodity name: Seamless Steel Pipe

Product Description

Description of Seamless Steel Pipe

Seamless steel pipes are perforated from whole round steel, and steel pipes without welds on the surface are called seamless steel pipes. According to the production method, seamless steel pipes can be divided into hot-rolled seamless steel pipes, cold-rolled seamless steel pipes, cold-drawn seamless steel pipes, extruded seamless steel pipes, and top pipes. According to the cross-sectional shape, seamless steel pipes are divided into two types: round and special-shaped. Special-shaped pipes include square, oval, triangular, hexagonal, melon seed, star, and finned pipes. The maximum diameter is 900mm and the minimum diameter is 4mm. According to different purposes, there are thick-walled seamless steel pipes and thin-walled seamless steel pipes. Normally, seamless pipes can withstand 20% higher working pressure than welded pipes of the same material grade and size.

Types of Seamless Steel Pipe from Our Factory

| Types | Uses |

| Structure Purposes | General structure and mechanical |

| Liquid Services | Petroleum, gas and other fluids conveying |

| Low and Medium Pressure | Steam and boiler manufacturing |

| Hydraulic Pillar Service | Hydraulic support |

| Auto Semi-shaft Casing | Auto sem-shaft casing |

| Line Pipe | Oil and gas conveying |

| Tubing and Casing | Oil and gas conveying |

| Drill Pipes | Well drilling |

| Geological Drilling Pipes | Geological drilling |

| Petroleum Cracking Tubes | Furnace tubes, heat exchangers |

Standards and Applications

| Standards | Grades | Class |

| API | API 5L | Line pipe for pipeline transportation systems |

| API 5CT | Tubing and casing for wells | |

| API 5DP | Drill Pipe for well drilling | |

| ASTM | ASTM A53 | Used as structural steel or for low-pressure plumbing |

| ASTM A106 | seamless carbon steel pipe for high-temperature service | |

| ASTM A335 | for seamless ferritic alloy-steel pipe for high-temperature service | |

| ASTM A213 | for seamless ferritic and austenitic alloy-steel boiler, superheater, and heat-exchanger tubes | |

| ASTM A179 | for seamless Cold-drawn low-carbon steel heat-exchanger and condenser tubes | |

| ASTM A192 | for seamless carbon steel boiler tubes for high-pressure service | |

| ASTM A210 | for seamless medium-carbon steel boiler and superheater tubes | |

| ASTM A333 | for seamless steel pipe for low-temperature service and other applications with required notch toughness | |

| ASTM A519 | for seamless carbon and alloy steel mechanical tubing | |

| ASTM A252 | for seamless and welded steel pipe piles | |

| DIN | DIN 17175 | for heat resistant seamless steel pipe lines |

| DIN 1629 | for seamless circular tubes of non alloys steels wth special quality requirements | |

| DIN 2391 | for cold drawn or cold rolled precision seamless steel tubes | |

| JIS | JIS G3454 | seamless carbon steel pipe for pressure service |

| JIS G3456 | seamless carbon steel pipe for high temperature service | |

| JIS G3461 | seamless carbon steel pipe for boiler and heat exchanger | |

| EN | EN 10210 | for hot finished seamless structural hollow sections of non-alloy steels |

| EN 10216 | seamless steel tubes for pressure purposes | |

| BS | BS 3059 | for carbon,alloy and austenitic stainless steel tubes with specified elevated temperature properties |

Dimension Tolerances of Seamless Steel Pipe

| Pipe types | Pipe Size (mm) | Tolerances | |

| Hot rolled | OD | <50 | ±0.50mm |

| ≥50 | ±1% | ||

| WT | <4 | ±12.5% | |

| ≥4~20 | +15%, -12.5% | ||

| >20 | ±12.5% | ||

| Cold drawn | OD | 6~10 | ±0.20mm |

| 10~30 | ±0.40mm | ||

| 30~50 | ±0.45 | ||

| >50 | ±1% | ||

| WT | <1 | ±0.15mm | |

| >1~3 | + 15%, - 10% | ||

| >3 | + 12.5%, - 10% | ||

Tube For Structural Purposes

Sizes: Out Diameter: 1-1/4""-16"", Wall Thickness: 0.109""-0.562""

Standard: ASTM A53, ASTM A106, ASTM A500/501-98, ASTM A519-98, JIS G3441-1994, JIS G3444-1994, BS EN 10210-1

Application: Used in the general structure and the mechanism, including construction, machinery, transportation

Boiler Pipe

Sizes: Out Diameter: 6.0mm-114.0mm, Wall Thickness: 1.0mm-15.0mm

Standard: GB3087-1999, ASTM A179, ASTM A106, JIS G3454

Application:Used for manufacturing superheated pipelines, the steam pipe, boiling water tube, flue tube, small flue tube, etc.

Seamless Steel Tubes for Liquid Service

Sizes: Out Diameter: 19.05-168.3mm, Wall Thickness: 2.31-14.27mm

Standard:GB/T8163-1999, ASTM A53-98, JIS G3452-1998, JIS G3454-1998, ASTM A106, DIN 1629-1984

Application:For conveying of petroleum, gas and other fluids

Line Pipe

Sizes: Out Diameter: 73-630mm, Wall Thickness: 6-35mm

Standard: API 5L

Application: For gas, water, transportation in Petroleum and natural gas industries

Drill Pipe

Sizes: Out Diameter: 2-7/8""-6-5/8"", Wall Thickness: up to 0.813""

Standard: API 5D

Application: For well drilling

Petroleum Cracking Tube

Sizes: Out Diameter: 1.315""- 20"", Wall Thickness: 0.133""-0.500""

Standard: GB9948-1988

Application: For manufacturing of furnace tubes, heat exchangers and pipelines in refineries"

Chemical Composition and Mechanical Properties

| Standard | Grade | Chemical Components (%) | Mechanical Properties | |||||||||

| c | Si | Mn | P | S | Mo | Cr | V | Tensile STrength(Mpa) | Yield STrength(Mpa) | Elongation (%) |

||

| ASTM A53 | A | ≤0.25 | / | ≤0.95 | ≤0.05 | ≤0.06 | ≤0.15 | ≤0.40 | ≤0.08 | ≥330 | ≥205 | ≥29.5 |

| B | ≤0.30 | / | ≤1.2 | ≤0.05 | ≤0.06 | ≤0.15 | ≤0.40 | ≤0.08 | ≥415 | ≥240 | ≥29.5 | |

| tandard | Grade | Chemical Components(%) | Mechanical Properties | |||||||||

| c | Si | Mn | P | S | Mo | Cr | V | Tensile STrength (Mpa) |

Yield STrength (Mpa) |

Elongation(%) | ||

| ASTM A106 | A | ≤0.30 | ≥0.10 | 0.29-1.06 | ≤0.035 | ≤0.035 | ≤0.15 | ≤0.40 | ≤0.08 | ≥415 | ≥240 | ≥30 |

| B | ≤0.35 | ≥0.10 | 0.29-1.06 | ≤0.035 | ≤0.035 | ≤0.15 | ≤0.40 | ≤0.08 | ≥485 | ≥275 | ≥30 | |

| Standard | Grade | Chemical Components(%) | Mechanical Properties | ||||||

| c | Si | Mn | P | S | Tensile STrength(Mpa) | Yield STrength(Mpa) | Elongation(%) | ||

| ASTM A179 | A179 | 0.06-0.18 | / | 0.27-0.63 | ≤0.035 | ≤0.035 | ≥325 | ≥180 | ≥35 |

| Standard | Grade | Chemical Components(%) | Mechanical Properties | ||||||

| c | Si | Mn | P | S | Tensile STrength(Mpa) | Yield STrength(Mpa) | Elongation(%) | ||

| ASTM A192 | A192 | 0.06-0.18 | ≤0.25 | 0.27-0.63 | ≤0.035 | ≤0.035 | ≥325 | ≥180 | ≥35 |

| Standard | Grade | Chemical Components | Tensile STrength(min) | Yield Strength(min) | |||

| C | Mn | P | S | Mpa | Mpa | ||

| API 5LPSL1 | A | 0.22 | 0.9 | 0.03 | 0.03 | 331 | 207 |

| B | 0.28 | 1.2 | 0.03 | 0.03 | 414 | 241 | |

| X42 | 0.28 | 1.3 | 0.03 | 0.03 | 414 | 290 | |

| X46 | 0.28 | 1.4 | 0.03 | 0.03 | 434 | 317 | |

| X52 | 0.28 | 1.4 | 0.03 | 0.03 | 455 | 359 | |

| X56 | 0.28 | 1.4 | 0.03 | 0.03 | 490 | 386 | |

| X60 | 0.28 | 1.4 | 0.03 | 0.03 | 517 | 414 | |

| X65 | 0.28 | 1.4 | 0.03 | 0.03 | 531 | 448 | |

| X70 | 0.28 | 1.4 | 0.03 | 0.03 | 565 | 483 | |

| Standard | Grade | Chemical Components | Tensile STrength(min) | Yield Strength(min) | |||

| C | Mn | P | S | Mpa | Mpa | ||

| API 5L PSL2 | B | 0.24 | 1.2 | 0.025 | 0.015 | 414 | 241 |

| X42 | 0.24 | 1.3 | 0.025 | 0.015 | 414 | 290 | |

| X46 | 0.24 | 1.4 | 0.025 | 0.015 | 434 | 317 | |

| X52 | 0.24 | 1.4 | 0.025 | 0.015 | 455 | 359 | |

| X56 | 0.24 | 1.4 | 0.025 | 0.015 | 490 | 386 | |

| X60 | 0.24 | 1.4 | 0.025 | 0.015 | 517 | 414 | |

| X65 | 0.24 | 1.4 | 0.025 | 0.015 | 531 | 448 | |

| X70 | 0.24 | 1.4 | 0.025 | 0.015 | 565 | 483 | |

| X80 | 0.24 | 1.4 | 0.025 | 0.015 | 621 | 552 | |

Production strength

Customized Process

Consult customer service

Communication details

Determine the plan

Product quotation

Product sampling

Determine the sample

Order payment

Determine delivery date

Volume production

Timely delivery

After-sale service

After-sales evaluation

Customer feedback

FAQ

Are you a manufacturer or trading company?

We are manufacturer.

What are your strengths?

First of all, we are manufacturer, so the prices are more competitive than trading companies.

Second, communicating with the factory is very effective, which will save you more time.

Third, we also have several partners who provide related products to meet your needs.

Where is your factory located?

Our factory is in Cangzhou City, Hebei Province, China. It is near to Tianjin Port, so the transportation is very convenient.

I want to make our logo on the product, is it okay?

Yes, it's totally okay. We can provide OEM. What you should do is sending us your logo, brand name or picture. Leave other things to us.

Delivery

Key words:

What Else Might You Need?